The machine performs the centrifugation process to separate the floury endosperm adhered to the bran without damaging it, thus minimizing the starch content in the waste and providing high flour yield.

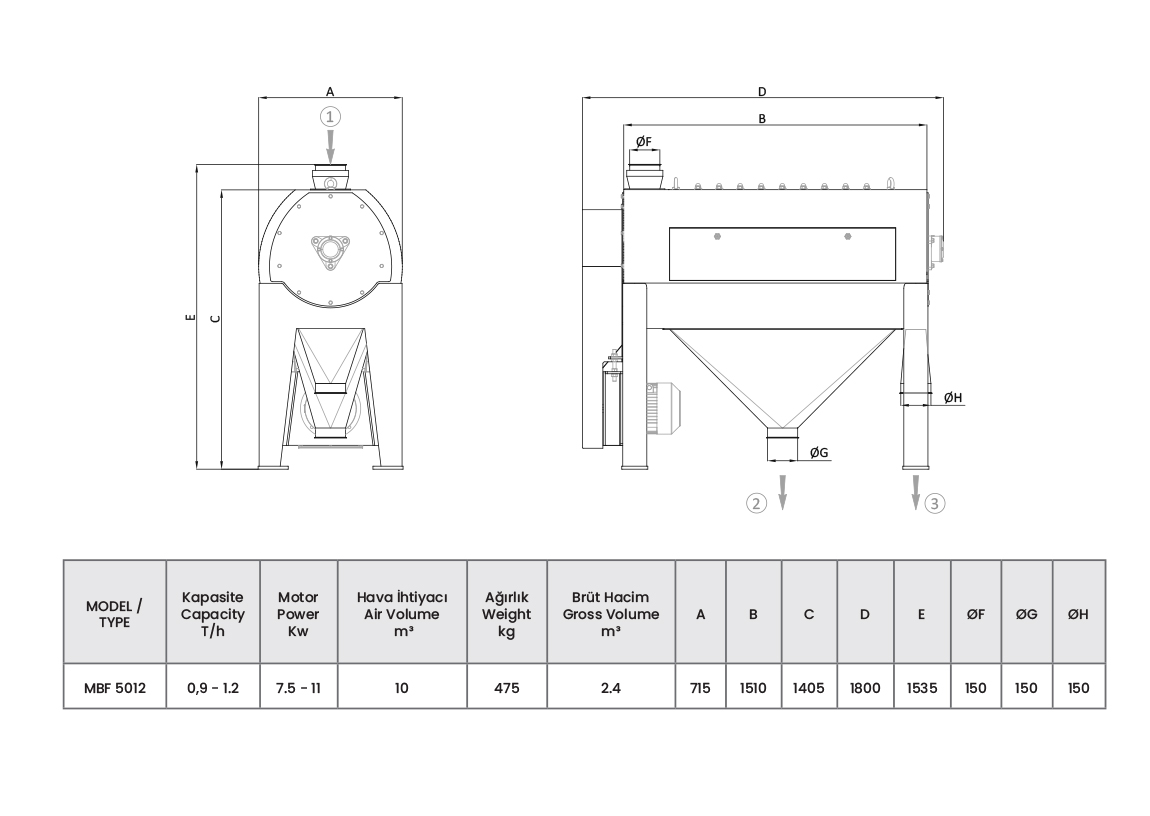

It is used to separate the pieces of flour stuck to the bran. Thus, the efficiency of the grinding system is increased. By using a sieve all around the rotor, the sieving area has been enlarged and the capacity has been increased. There are two large inspection hatches on both sides. In this way, the control and replacement of the facilitated.The rotor allows the flour to be separated from the bran by hitting the product entering the machine onto the sieve and adjustable pallets. Thanks to the externally adjustable pallets, the sieving capacity and efficiency can be increased by changing the time the product stays in the machine.