For dust-laden air in the volume range of approximately 5~600 m³/min.The filter is used for removing dust particles from dust/gas mixtures. The round filter housing allows a first seperation by means of centrifugal force. The subsequent filtration through the filter fabric puriflies the air to a high degree, fully meeting today’s environmental protection legislation.

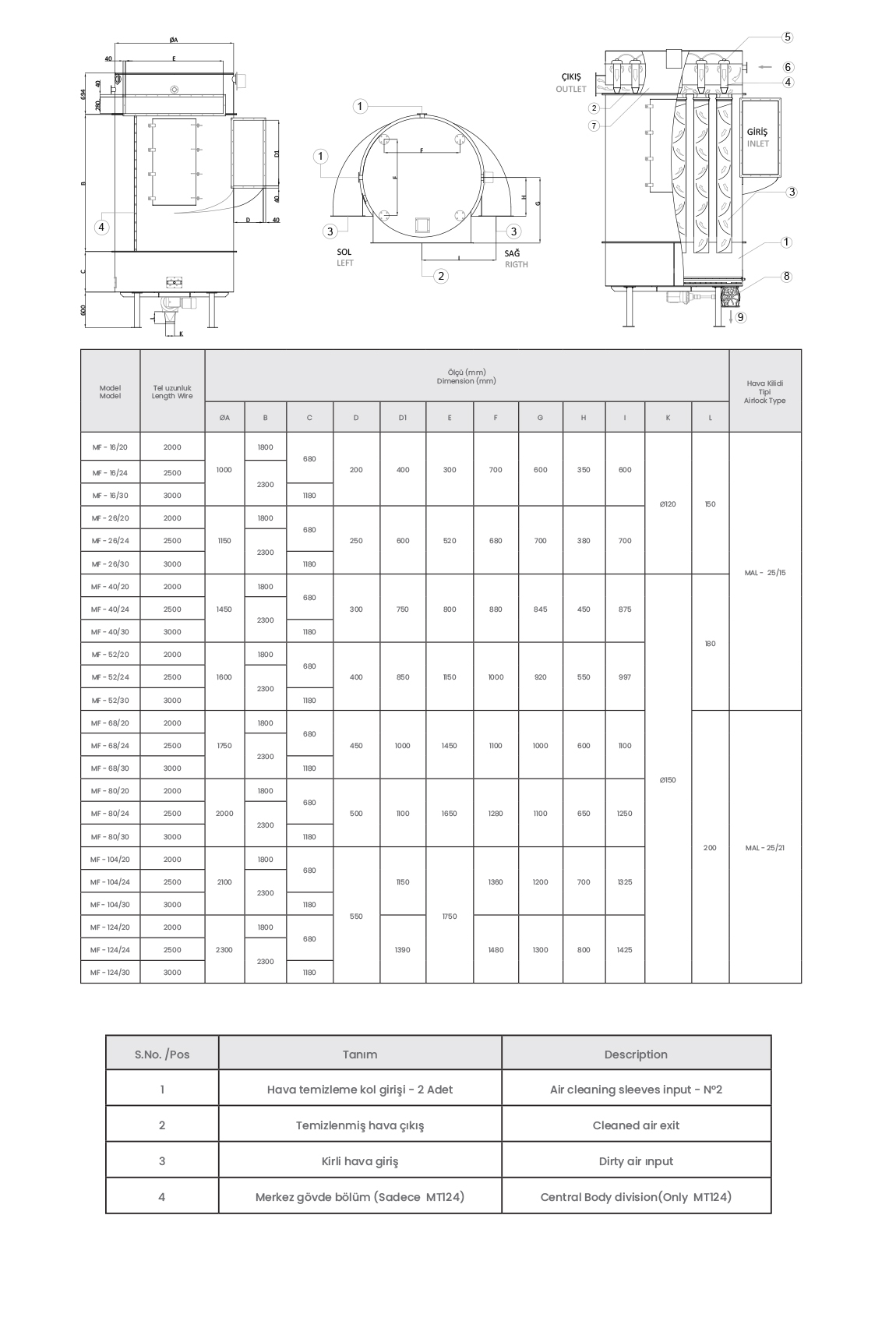

KEY OF DRAWING

1. Dust-air chamber

2. Clean-air chamber

3. Filter bags

4. Rinsing-air nozzles

5. Rinsing-air valves

6. Low-pressure rinsing-air

7. Integrated rinsing-air tank

8. Discharge airlock

9. Dust outlet

ADVANTAGES

a. Proven high load capacity of the filter

b. Maximum cleanoff of the filter bags

c. High degree of prutiy of the cleaned air, due to filter fabrics product.

d. Rinsing air tank integrated in the filter, no additinoal tank requited. Simple generation of rinsing-air by means of rotary piston or periphery blows.

e. Bag filters as total seperatos at the receiver end of pneumatic conveying systems, or as aspriration filters, insert filters, or bin-mounted filters.

FEATURES

1. Operating pressures :

• Negative pressure up to 0.3 bar

• Positive pressure up to 0.3 bar

• Reinforced desing for higher pressures.

• Bag-cleanoff by means of oil-free and condensate-free low-pressures rinsing air, 0.4~0.6 bar.

• Electronic-fluidic rinsing system with high-efficiency reverse-air cleaning. 2. Rinsing-air consumption :

• 40x45 Nlt bag x pulse.