- High sifting capacity, absorption height to sit the volume of the stock by using different

- Frame heights and intermediate frames.

- Excellent sifting efficiency.

- Up to 28 sieves per compartment.

- Sieves frames are easy to insert and remove.

- Convenient and reliable tightening of the sieve stacks by means of patented clamping device and detachable hand cranks.

- Two kinds of drive.

- Compact and handy design of sieve frames and insert frames of a plastic wood composition.

- Easy adjustment of the flow pattern by turning or changing the individual square sieve frames.

- Good surface insulation.

- Unobjectionable sanitation.

- Easy to clean.

- Requires minimum maintenance.

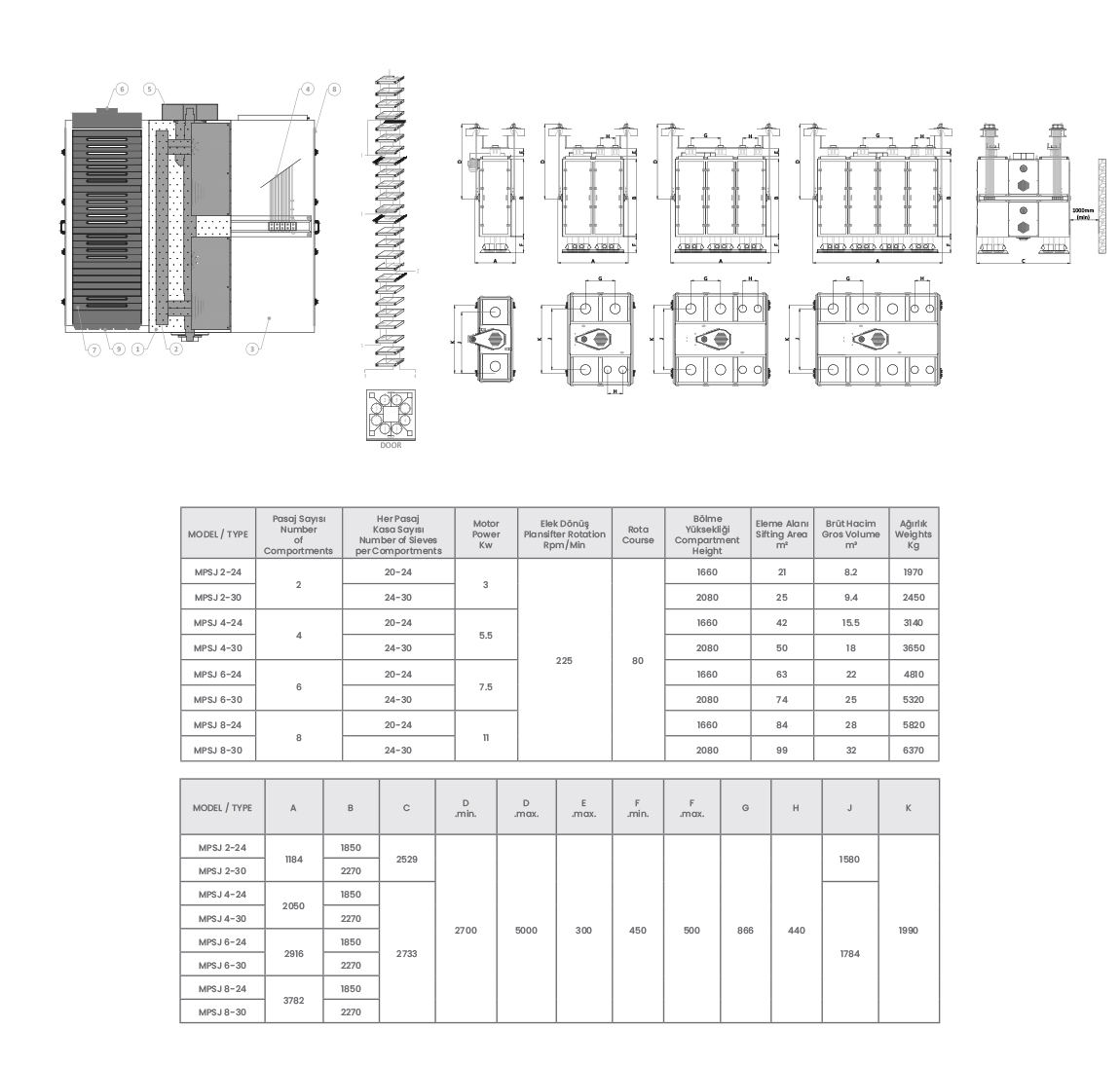

1. Central supporting structure

2. Counter weights

3. Sifting section

4. Suspension canes

5. Power

6. Material inlet

7. Sieves

8. Access doors to sifting section

9. Material outlet

- In wheat rye and corn (maize) mills etc…

- Grading of barley.

- Grading of coffette beans.